Grocery group Ahold Delhaize will roll out small automated warehouses to speed order-picking and cut delivery times, Reuters has learned, as it revamps its e-commerce business in response to rising competition in a fast-growing sector.

At an investor event on 13 November, the world's eighth-biggest food retailer is set to showcase a partnership that will allow it to automate order collection at mini 'robot supermarkets' attached to the stores of its US chains, like Stop & Shop.

That marks a departure from its previous strategy of relying more on manual labour at bigger warehouses, or on a mixture of man and machine, to meet online food orders.

Now Netherlands-based Ahold Delhaize is teaming up with Takeoff, a start-up that builds small warehouses that stack groceries to the ceiling to save space, and uses robot arms to assemble shoppers' orders for items such as beer, milk, bread and fruit.

Condensed Supermarkets

The warehouses serve as condensed supermarkets that can supply several stores with click-and-collect orders. They cost about $3 million (€2.6 million) to build, which Takeoff says is less than the cost of a typical store revamp.

"Ahold is preparing for a major push," said Curt Avallone, Takeoff's chief development officer, who led digital innovation at Stop & Shop until 2003.

"If it goes well, both from their side and our side, the hope is [that] we would rapidly be able to build quite a few [warehouses]," added Avallone.

Ahold chief executive Frans Muller confirmed the deal on Wednesday and said that it should help expand online faster and at a lower cost than standalone warehouses.

"With the robotised solution, we can optimise those picking costs and be closer with micro-fulfilment to our catchment areas. We also reduce the cost of the last mile," Muller said.

Ahold's shares jumped 5% on Wednesday, as it reported third-quarter results that beat analysts' forecasts, lifted by strong online sales and growth in its key markets.

Online Grocery War

Ahold's move is the latest salvo in a war for the online grocery market that has escalated since Amazon's takeover of Whole Foods last year. Whole Foods since launched same-day grocery delivery with Amazon's Prime Now in more than 60 cities.

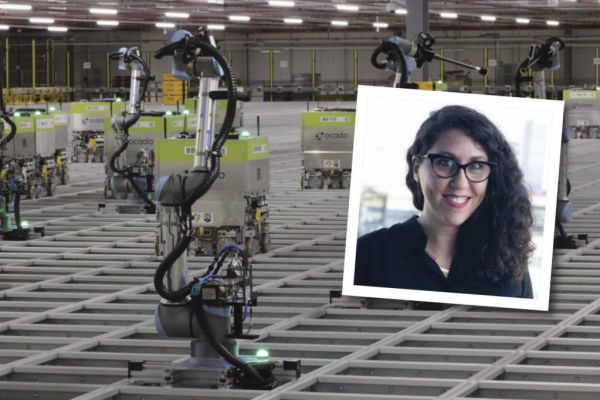

Other retailers are also racing to respond. Walmart will test Alert Innovation’s Alphabot automated grocery-picking at a store in New Hampshire, and Kroger has teamed up with British online grocery expert Ocado.

Kroger said that it will disclose the location for the first three US sites out of the planned 20 high-tech Ocado warehouses in the next couple of weeks. They will take about two years to build, and each costs Ocado about $39 million (€34 million).

Ahold Delhaize, the operator of US chains such as Giant Food, Food Lion and Hannaford, acquired Chicago-based online grocer Peapod, which is still the market leader, in 2000.

However, growth has slowed at Peapod since Amazon bought Whole Foods and as supermarkets (including Ahold's own chains, like Stop & Shop) team up with start-ups like Instacart to offer kerbside pickup, or one- to two-hour delivery.

Ahold reported that US online sales growth picked up in the third quarter, but Muller said that he was still not happy with that.

Hand To Mouth

Until now, Ahold's strategy has been largely manual. At its warehouses, known as 'dark stores', pickers grab items from shelves and put them into crates for packaging and delivery.

Ahold Delhaize has decades of experience in delivering groceries to people's homes, starting in the Netherlands in 1986, when its Albert Heijn chain took orders by phone or fax.

At one Albert Heijn warehouse outside the Dutch city of Eindhoven, pickers each grab an average of one product every ten seconds, walking about 4.5 kilometres a day. Algorithms work out the shortest path through the aisles and try to minimise trolley congestion.

Pawel Kamienczuk, a 28-year-old order-picker from Poland, sweats as he races down an aisle, trying to meet a target of 380 items an hour.

"At the beginning, it took time to get used to it, but now I don't feel tired," Kamienczuk said.

Kamienczuk wears a device like a smartphone on his wrist, which tells him where to go and which items to grab next.

He scans each product with a device mounted on his forefinger and puts it into one of 18 blue crates stacked on a large trolley.

Albert Heijn warehouses can pick and pack 135-140 units per labour hour, lower than Kamienczuk's rate because it takes into account work done by others to unload supplies, stack shelves, assemble orders and pack delivery vans.

The figure is also lower than the 163 units that Ocado reported for the first half of 2018, but analysts say that it is impressive, given than Albert Heijn's capital outlay for its centres is a fraction of the cost of Ocado's automated warehouses.

Scarcity Of Workers

Efficiency is key at a time when labour costs are rising in the United States and Europe.

The Dutch jobless rate is at an 18-year low, US unemployment is around the lowest in five decades, wage pressures are rising, and companies are increasingly complaining about a scarcity of workers.

Last month, Amazon said that it would raise the minimum wage for US workers to $15 an hour, in part to attract staff.

At Ahold's Peapod warehouse in Jersey City, pickers who start on about $12 per hour with benefits can make up to an extra $3.50 an hour if they beat speed targets, but they are also closely monitored for quality – a dented tin could mean a refund.

"When we shop, we have many people that check after us," said Amal, an expert 'shopper' who specialises in selecting bananas, Peapod's top-selling product.

The Peapod warehouse in New Jersey is the firm's biggest and most sophisticated to date, in terms of automation.

There, crates move along conveyer belts to teams of pickers who focus on different food categories, while robots add non-food items like shampoo. Peapod does not share pick times.

Despite the automation, Peapod employs 825 people there, working two shifts – from 5 a.m. until 2 p.m., and from 5 p.m. until 2 a.m. – in a warehouse with seven temperature zones.

Next-Day Versus Same-Day

Peapod has only offered next-day delivery so far. The partnership with Takeoff will enable the group to offer same-day delivery or click-and-collect, initially, to customers living near a pilot warehouse at a Shop & Stop in Connecticut.

Avallone declined to comment on the financials of the Ahold deal, but said that Takeoff should be able to roll out the concept quickly, as it takes 16-20 weeks to set up its 10,000-square-foot warehouses, which can handle up to $50 million (€43.6 million) in annual sales.

That contrasts with Ocado's newest facility in Britain, which is a 563,000-square-foot site with a potential annual turnover of £1.2 billion (€1.4 billion).

The US grocery e-commerce market is still in its infancy, at just 1.6% of sales, but it is expected to more than double by 2023, according to industry research group IGD.

Ahold, which makes almost two thirds of its sales in the United States, wants to boost e-commerce sales to €5 billion ($5.8 billion) by 2020, or about 8% of total turnover, from €2.8 billion in 2017. It will update that target next week.

Its US online sales should near $1 billion by the end of the year, as it creates a shared e-commerce infrastructure for all of its store-based brands, along with its online grocery site, Peapod, Muller said in August.

News by Reuters, edited by ESM. Click subscribe to sign up to ESM: European Supermarket Magazine.